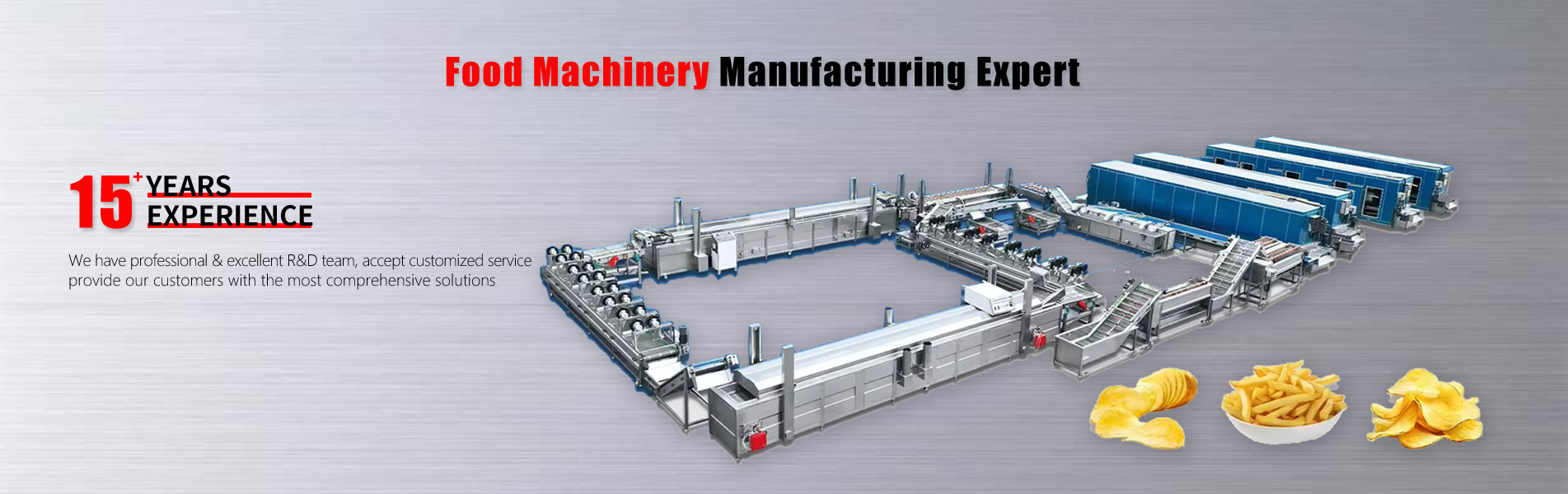

Small Frozen French Fries Plant

Small Frozen French Fries Plant

The semi-automatic frozen French fries line becomes popular for its remarkable profit. Compared to the fully automatic line with the same capacity, the investment is lower.

Output capacities for choice: 100 kg/h

We can supply you with the formula for making frozen french fries for free.

Besides potatoes, the raw materials could be sweet potato, carrot, cassava, and other vegetables.

Has advantages like low one-time investment, low energy consumption, multi-function, small volume, high profits, easy to use and maintain, etc.

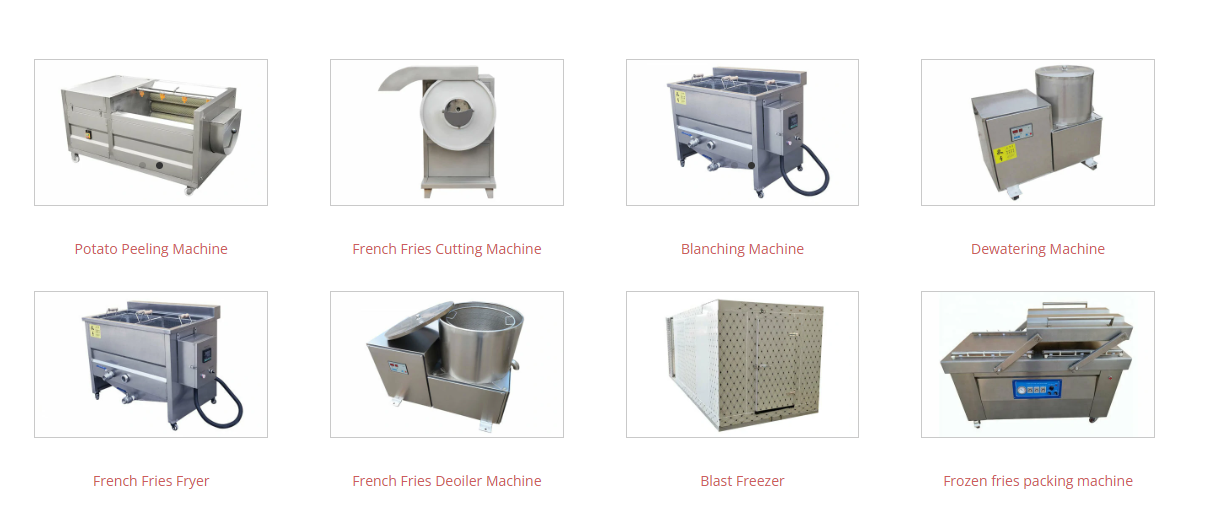

Functions of Machines in the Small Frozen French Fries Line

1.Washing & Peeling: to wash away the sand and soil and remove the potato skin.

2.Cutting: to cut potatoes into fries. Thickness 7*7-12*12mm.

3.Blanching: to blanch the french fries in hot water to deactivate enzymes, temperature: 90-95℃, time: 60-90 seconds.

4.Dewatering: to remove the extra water from the chips

5.Frying: to fry the french fries slightly, frying temperature: 170-180 ℃, frying time: 40-60 seconds.

6.Deoiling: to remove the extra oil from the fries.

7.Freezing: this machine is to freeze the french fries in -30~-35℃; feeding temperature:+20℃, output temperature:-18℃; freezing time: 30-50min/batch.

8.Weighing and Sealing: to weigh and pack the french fries with pre-made bags.

1.We have various choices for different machines of washing peeling, cutting, blanching, frying, dewatering, deoiling, and packing, etc. we can supply you with the line according to different requirements.

2.A potato cutting machine can process both raw potato chips and French fries.

3.The thickness of French fries can be adjustable.

4.Blanching temperature, blanching time, and frying time can be adjusted for the best flavor.

5.The blanching time is adjustable.

Raw potato strips are blanched in boiled water to remove the vegetable scent. High blanching temperature would eliminate bacterially and keep the original flavor.

6.Low investment budget.

The small-scale frozen French fries line does not require too many workers for general production, and the purchasing cost is low. The independent factory building is not necessary.

7.Flexible production process.

For it is a semi-automatic production line, the french fries making process is not restricted by the size and the location of the factory;

You can determine how many kgs of french fries to make per hour or per day according to the needs of your customers.

8.Fast income and high profit.

French fries are a snack in almost every restaurant, be it locally or globally. So you can sell your french fries quickly to realize cost-return and profitability within a short time.

English

English Spanish

Spanish